Design strategies for metal wall and roof systems

Versatility, reliable performance, and relatively low installed-costs make prefabricated metal panel wall and roof systems attractive for sophisticated building applications.

Years ago, prefabricated metal panel wall and roof systems did not find wide acceptance in high-end commercial applications. While these systems were cost-effective, aesthetic perceptions relegated them to large storage buildings, manufacturing facilities, and big box stores. However, versatility, reliable performance, and relatively low installed-costs have now made these systems attractive in more sophisticated applications.

Today, owners and architects often collaborate to use these products in distinctive and aesthetically innovative design solutions. Manufacturers, recognizing an opportunity, have expanded their product lines with the aim of amplifying product use across a range of building types. Of course, no building enclosure system is without design challenges and considerations.

THIS COURSE IS SUPPORTED BY:

From structural and weatherproofing to energy efficiency, the longevity and performance of metal wall and roof systems depends on an understanding of material properties, code requirements, and best practices.

Metal Walls and Roof Materials and Finishes

Most metal wall and roof systems are proprietary, each manufacturer having their own profiles, method of attachment, and performance specifications. However, there are basic similarities in these assemblies.

Metal systems come in a variety of materials, with aluminum being the most common due to its relative durability, corrosion resistance, and light weight. Aluminum panels are available in flat plates—solid plate approximately one-eighth inch thick—or composite panels, where foam insulation is sandwiched between two layers of thin sheet aluminum.

Steel is another commonly used material. Strong and providing superior impact resistance, steel is often selected for façades in high-traffic areas and for roofs that must span longer distances between supports. However, steel’s strength means it is heavier than other materials, necessitating more underlying structure to support the load. Steel also requires a protective coating to prevent deterioration due to corrosion.

Zinc panels are also becoming more popular because of the distinctive appearance and durability afforded by the surface patina acquired during weathering. Patina formation occurs naturally in the presence of moisture and carbon dioxide. Care should be taken where moisture may be present without sufficient carbon dioxide, such as at the underside of roof panels, where condensation and other incidental moisture can cause corrosion. This can also occur in areas that see significant amounts of water accumulation, such as gutters. When using zinc panels, protective coatings applied to the at-risk surfaces should be considered.

Copper is an extremely durable material option that generally does not require a protective coating. Although, as with zinc, the use of such coatings at the underside of panels can be advisable under certain conditions. Uncoated copper also tends to stain adjacent surfaces and materials over time.

Stainless steel never requires a protective coating and provides a bright appearance. An aesthetic alternative is terne plate, stainless steel coated with an alloy that is over 99% tin. Terne plate provides a weathered appearance similar to zinc but, like zinc, requires ventilation behind the panels to prevent pitting and corrosion.

Depending on the material used, any number of finishes and coatings may be selected based on aesthetic and performance requirements. Paints, such as fluoropolymers, enjoy wide use in metal wall applications, as they come in a range of colors, and are resistant to fading.

Porcelain enamel coatings fuse powdered glass to the metal surface at a high temperature. Like fluoropolymers, they are durable and offer designers a number of appearance options.

Many finishes have been developed more for their protective properties than for their appearance options. Galvanizing, for instance, is a sacrificial protective coating of zinc applied to steel that has a silver-gray appearance and is used to prevent corrosion of the underlying steel. Anodizing, an electrolytic process used on aluminum to increase its corrosion resistance, is only available in a limited range of colors (typically black, bronze, and silver).

It’s important to remember that not all finishes are compatible with all materials. Even when an appropriate coating or paint is selected, application timing can significantly impact longevity. Typically, it is best to apply coatings and paints after the metal has been formed, to avoid hairline breaks in the material at bends.

Prefabricated Metal Wall Systems

Generally speaking, there are two types of metal wall systems available: “closed” and “open.”

Closed assemblies (also called “barrier” or “face-sealed” systems) use the metal wall panels to resist the infiltration of weather (air and water) into the building. The metal wall panel system is the air and moisture barrier of the façade. To achieve weather protection, the joints between the metal panels must be sealed to form a comprehensive barrier.

Open systems, as the name implies, do not provide the primary protection against air and moisture infiltration. In these applications, a secondary means of protection must be included behind the panels, with consideration given to the way in which moisture that permeates the cladding can be directed back to the exterior. Rainscreens are a common form of open system that have become increasingly popular in the last decade.

How metal wall panel systems are installed and attached to the substrate (and ultimately to the building structure) is another defining element of their design. The panels are most commonly secured to a metal sub-framing system consisting of “z” girts, metal studs, or proprietary configurations. This securement can be achieved in two ways: by use of “exposed” or “concealed” fasteners.

With exposed fastener systems, panels are attached to the substrate using fasteners that are screwed through the panel and left exposed for ease of installation and aesthetic effect. While the fasteners are often gasketed to limit water infiltration, this method is most commonly employed in open panel systems.

Systems using concealed fasteners employ clips to secure panel ends to the sub-framing system with bolts. This method can provide a clean, uninterrupted look to the metal panel system in either closed or open assemblies.

Prefabricated Metal Roof Systems

Prefabricated metal roof systems are broadly defined as being either “hydrokinetic” or “hydrostatic.”

Hydrokinetic systems are not necessarily “water-tight.” These assemblies shed water by moving it across their surface and off the roof as quickly as possible. This requires that hydrokinetic roofs have adequate pitch to effectively move water and limit infiltration beneath panels. Since panel joints are not weathertight, hydrokinetic systems require a substrate/underlayment system to protect the interior of the building against incidental moisture that finds its way beneath the roof surface.

Hydrostatic systems, on the other hand, are water and air barriers that form the primary protection at roof level against weather infiltration into the building.

Metal roof systems are also classified by their ability to span between structural members. Architectural systems cannot span long distances and require a continuous substrate for support. As a result, these assemblies are often hydrokinetic, since the substrate that is required for support can also act as a surface for an underlayment protection system.

Structural systems can span between structural members without the assistance of a continuous substrate. The panels of these systems derive their strength in a variety of ways, including the use of stronger metals, thicker panels, raised panel ends, intermediate ribs, and corrugation in the panel profile. Since structural systems require no substrate, they are often hydrostatic.

Regardless of the system selected, metal roof panels are typically interlocked, or “seamed,” together. Examples of interlocking methods include flat seams, standing seams, and battens. In hydrostatic applications, seams may also be sealed using sealant or solder for additional weather integrity.

Metal wall and roof design considerations

Whether designing a prefabricated metal wall system, roof system, or both, the architect or engineer must address certain fundamental design considerations. While manufacturers can be instrumental in this effort, a design professional with knowledge of the building enclosure is often indispensable. The following is a brief list of some of the issues to be addressed during design.

• Structure. One of the primary considerations for building enclosure assemblies is their structural integrity. Façade and roof cladding systems must have the ability to resist a variety of forces to which they may be subjected, including gravity, seismic load, wind load, deflection, and inter-story drift. It’s important to remember that every component of the system, from the substrate to the fasteners to the panels themselves, must be considered when designing the cladding to meet the necessary structural requirements.

• Expansion. Metals will increase or decrease in size in response to a change in temperature. A metal’s tendency to be affected in this way is defined as its thermal expansion coefficient. The higher the coefficient, the more a material will expand or contract because of a change in temperature. Zinc and aluminum, for instance, have relatively high coefficients (19.0 and 13.1, respectively), while that of steel is relatively low (7.0). This means that zinc panels will expand nearly three times as much, and aluminum nearly twice as much, as steel.

Accommodation for such movement must be built into the design to avoid issues such as buckling, fastener failure, and deterioration of system integrity. Movement tolerance can be achieved in a variety of ways, including slotting of fastener openings, limiting the length of panel sections, and incorporating expansion joints.

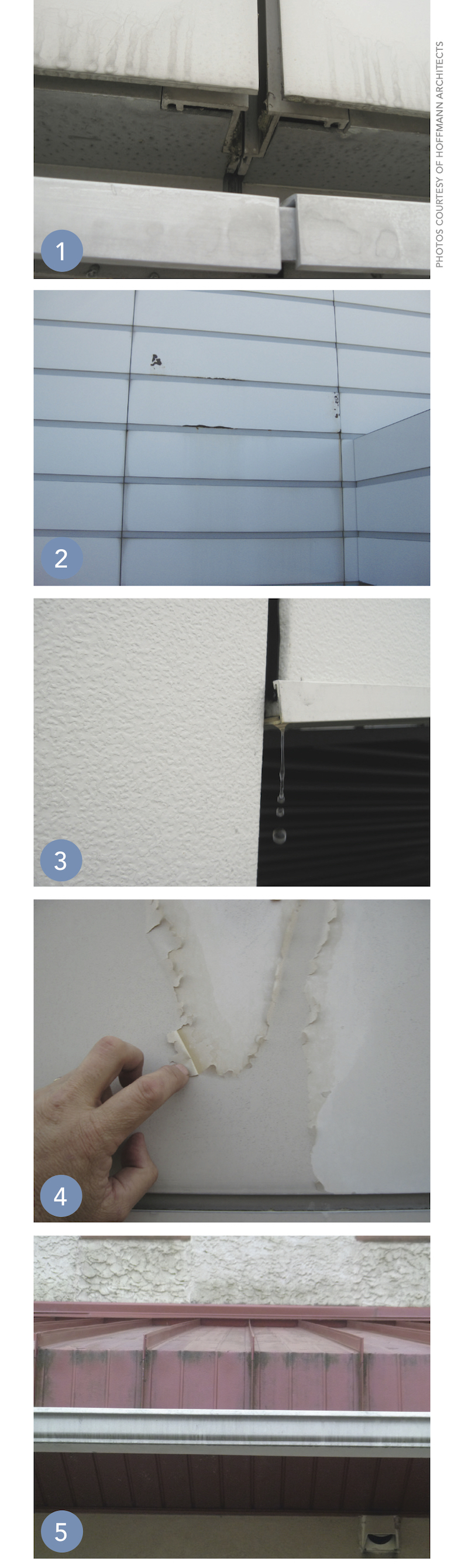

• Weather Integrity—the ability of roof and façade assemblies to resist the infiltration of air and moisture—is essential. As discussed earlier, these systems can be either “closed” (hydrostatic) or “open” (hydrokinetic). In either case, consideration of weather integrity and accommodation for moisture are necessary design challenges.

In prefabricated metal façades, “closed” or face-sealed barrier systems rely on a primary seal between joints—often seam tape or an elastomeric sealant system—to provide weather integrity. These primary seals between panels have a shorter life expectancy than the panels themselves and are therefore the first part of the system to fail. Consequently, they present an ongoing maintenance concern.

In “open” façade systems, the substrate behind the panels (often exterior-grade sheathing with a water-resistant coating or cladding over metal studs) acts as the primary protection against air and water infiltration. In such cases, water that will inevitably find its way behind the metal panels must be channeled to the exterior of the building through a system of flashing and weeping. Even with such protection in place, the volume of water that can infiltrate behind the panels should be limited.

Hydrostatic roof systems rely on the pitch of the roof and the integrity of the panel seams (often enhanced with seam tape, sealant, or solder) to keep water from infiltrating the building. Hydrokinetic systems also limit water infiltration through roof-pitch and the integrity of seams, but do not eliminate it. In such systems, an underlayment consisting of, for instance, #30 felt paper and a slip sheet (building paper), must be applied to the substrate to protect the building interior. In certain climates, membrane protection at the roof perimeter extending at least 24 inches onto the building must also be considered to limit the deleterious effects of ice.

Steep-sloped roofs must include adequately sized and configured gutters, leaders, and downspouts to remove water that collects on the surface or substrate. Gutters can be external or “built-in” (concealed).

Lastly, “weather integrity” includes not just resistance to moisture, but to air. Most governing authorities now have specific requirements limiting the flow of air through the building enclosure. As with moisture protection, closed systems rely on the metal panel system to resist such air flow, while open systems depend on a substrate barrier for preventing air infiltration.

• Thermal Performance. Building enclosures must meet increasingly stringent requirements regarding energy and thermal performance. Metal systems benefit from having a low thermal mass; however, they are not very good insulators. Therefore, the use of insulation within the assembly must be a consideration during design. Typically, the insulation is installed between the metal panels and the underlying substrate, and is comprised of mineral wool or foam plastics such as extruded polystyrene or polyisocyanurate.

Energy performance requirements vary depending on climate zone and the model building code adopted in a region. In New York City, for instance, roof assemblies must include insulation with a thermal resistance of at least R-30. Metal-framed walls must include R-7.5 of continuous insulation, plus an additional R-13 of insulation between the sub-framing studs.

As much of prefabricated metal panel wall and roof systems are, by definition, metal, linear and point transmittances (thermal shorts that transfer energy between the interior to the exterior of the building) should be considered and eliminated to the greatest extent possible. Such measures also help reduce the potential for condensation within the assemblies.

Because of the need to attach the panels to the substrate, often by means of metal girts, insulation within the assembly is frequently interrupted, causing thermal shorts and reducing the overall efficiency of the wall or roof. In such cases, isolators, typically in the form of lightweight, highly porous coatings called aerogels, can be applied to the sub-framing system to reduce the transfer of energy along its surface.

• Condensation. The potential for condensation to develop within the façade or roof system must be considered during design and measures taken to limit the deleterious effects of such moisture. While providing adequate ventilation behind or beneath the panels is sometimes sufficient, a correctly designed and installed vapor retarder is often necessary.

• Sound Attenuation. Typically, metal panel systems are not very effective at mitigating the transfer of sound. During design, the STC (“sound transmission class”) or OITC (“outdoor/indoor transmission class”) rating for the project should be established and the sound attenuation properties of the system identified. Measures can then be taken to enhance the properties of the assembly through, for instance, the incorporation of additional insulation or air cavities.

• Combustibility. The use of certain building materials within a prefabricated metal panel enclosure system (such as foam plastics as insulation or a core material in composite metal panels) may present issues with combustibility. The design professional should reference the applicable code for requirements governing the combustibility of such assemblies. Keep in mind that it is not just the assembly itself that must conform to these requirements; detailing of the transition to adjacent building systems (such as between floors and between walls and roofs) must be considered to achieve the required fire protection across the entire exterior envelope.

• Appearance. While this article focuses on the technical aspects of metal wall and roof systems, appearance is nonetheless an essential design consideration. Technical considerations can affect that overall appearance, and care should be taken to avoid choices that can have a detrimental effect on aesthetics.

Consult with manufacturers regarding the potential for issues such as telegraphing, where the outline of underlying stiffeners or fasteners appear on the surface of the metal panel, or oil-canning, a wavy or dimpled appearance on the surface of the panel.

• Snow and Ice Accumulation. In certain climates, the potential for snow and ice to build up on roofs is a concern. Such accumulations can damage perimeter assemblies and fall from the building, creating a hazard.

Improper drainage design can often lead to such build-up at roof edges. Gutters and leaders that are too small or configured incorrectly cannot adequately remove runoff before it refreezes, resulting in large accumulations of ice at gutters and eaves that can damage perimeter assemblies and infiltrate the building through a process known as “ice jacking.” During design, calculations should be performed to ensure that the roof’s drainage system is adequately sized and that gutters are configured in accordance with recognized standards such as the Sheet Metal and Air Conditioning Contractors’ National Association Architectural Sheet Metal Manual.

Even with an adequately designed drainage system, the potential for accumulation of snow and ice in amounts large enough to be a danger still exists. Consideration should be given to incorporating an appropriate snow guard system into the roof design to limit this possibility. As with a roof’s drainage system, calculations must be performed to affirm that the system is restraining snow and ice in a manner that will promote gradual release of runoff over time and limit accumulation in any one area of the roof. Ideally, such systems should not penetrate the metal roof panels.

Proper attic ventilation helps to prevent ice dam formation at eaves, alleviating strain on the snow guard system and reducing the possibility of leaks.

• Dissimilar Metals. Different metals that come in contact with each other within the assembly can lead to corrosion, through galvanic action, and to staining, through water runoff. When the potential for galvanic action exists, dissimilar metals should be separated by a protective coating or other method.

• Sustainability. It’s important to note that many pre-manufactured metal panel systems include anywhere from 25% to 95% recycled material. At the end of their lifespan, most metal panel systems can be recycled again.

Testing and Mock-Ups of Metal panel systems

The complexity and performance requirements of enclosure systems, in general, and prefabricated metal panel systems, in particular, make mock-ups and testing a worthwhile consideration. The following is a summary of options available at various stages of design and construction.

Manufacturer’s test data and technical documentation

At the design phase, the manufacturer’s test data and technical documentation should be provided. This allows the design team either to confirm that the proposed assembly can meet the various project requirements or to identify key information that might be missing. Incomplete technical documentation from the manufacturer may be an indication that the system is not appropriate for the application, or that additional testing is required to validate its use.

Visual Mock-Up (VMU)

During pre-construction, a visual mock-up (VMU) allows all stakeholders to observe a representative sample of the proposed system and approve it for aesthetics and design intent. The VMU should enable the team to confirm overall appearance, proportions, color, and texture, as well as the effectiveness of attempts to limit undesirable visual characteristics, such as “telegraphing” and “oil-canning.”

A VMU can be a project-specific mock-up fabricated on- or off-site, or it can be a similar system installed on a previous project, as identified by the design team and manufacturer.

Performance Mock-Up (PMU)

A performance mock-up (PMU) is a representative sample of the enclosure assembly installed at an off-site testing facility, where approved test methods can ascertain the system’s conformance with performance requirements, including structural integrity, thermal resistance, acoustics, and air and water resistance. PMU testing typically takes place concurrently with construction.

In short, a manufacturer’s published data provides an overview of a wall or roof assembly’s performance, but it is no substitute for independent verification testing. Pre-construction VMU testing establishes design parameters, while in-situ PMU testing during construction, for issues such as air and water resistance, provides validation that the system meets performance requirements.

More Campus Related Content

Structural

Waterproofing deep foundations for new construction

Below-grade waterproofing systems can be critical features of building enclosure design, particularly when the structure has a deep foundation. As…

course credit: 1.0 AIA LU/HSW

course credit: 1.0 AIA LU/HSW

Interior design/Interior architecture

Performance-based facilities for performing arts boost the bottom line

New technologies, innovations, and tools are opening doors for building teams interested in better and yet less-expensive performing arts facilities…

course credit: 1.0 AIA LU

course credit: 1.0 AIA LU

Exterior

For the Multifamily Sector, Product Innovations Boost Design and Construction Success

It seems fitting that wider adoption of thin-shell concrete, a technology popular worldwide but somehow unfavored in the U.S., has resulted from the…

course credit: 1.0 AIA LU/HSW

course credit: 1.0 AIA LU/HSW

Provided By: BD+C

Exterior

Fire safety considerations for cantilevered buildings [AIA course]

Cantilevered buildings seem to be everywhere in New York City these days, as developers and architects strive to maximize space, views, and natural…

course credit: 1.0 AIA LU/HSW

course credit: 1.0 AIA LU/HSW

Provided By: BD+C

Exterior

4 steps to a better building enclosure

Dividing the outside environment from the interior, the building enclosure is one of the most important parts of the structure. The enclosure not…

course credit: 1.0 AIA LU/HSW

course credit: 1.0 AIA LU/HSW

Provided By: BD+C

With affordability and innovation for all: Multifamily housing ideas break barriers

With a growing need for multifamily housing solutions at all income levels, the U.S. market is seeing a proliferation of inventive projects.…

course credit: 1.0 AIA LU/HSW

course credit: 1.0 AIA LU/HSW

Provided By: BD+C

Exterior

Metal cladding trends and innovations

Metal cladding is on a growth trajectory globally. This is reflected in rising demand for rainscreen cladding, which market research firm VMR values…

course credit: 1.0 AIA LU

course credit: 1.0 AIA LU

Provided By: BD+C

Structural

Flood protection: What building owners need to know to protect their properties

Historically, flooding is one of the costliest natural disasters in the United States on an annual basis. Flood Insurance Rate Maps (FIRMs) attempt…

course credit: 1.0 AIA LU/HSW

course credit: 1.0 AIA LU/HSW

Provided By: BD+C

Multifamily housing/Apartments/Condominiums

Urban housing revival: 3 creative multifamily housing renovations

Bruner/Cott’s AIA award-winning inaugural project, the 1974 transformation of Boston’s expiring Chickering & Sons Piano Factory into the Piano…

course credit: 1.0 AIA LU

course credit: 1.0 AIA LU

Provided By: BD+C

Structural

Steel structures offer faster path to climate benefits

Faster delivery of buildings isn’t always associated with sustainability benefits or long-term value, but things are changing. An instructive case is…